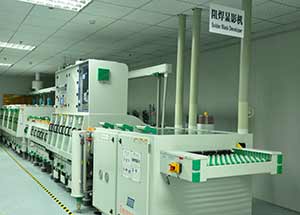

PCBWIN is a leading manufacturer of high quality quick-turn, high mix low volume PCB

We offer customers with various types of PCB customization such as high-speed, high-frequency, high-precision HDI,heavy copper pcb for power supply, special material rogers, Ta conic for communication and rigid flex etc.Individual production lines to guarantee quickest lead time for both protypes and production.

Our products are widely used in industrial automation, IOT, security control,communication, medical, nation defense filed and so on.

500000 +

Square meters per year

800 +

employees

30000 +

types of pcb per year

5000 +

customers

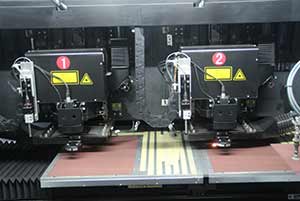

PCBWIN continually invest in the latest technology and equipment so as to be able to fabricate boards like micro-mechanical hole,blind-buried vias, copper-coin pcb, heave copper pcb, rigid-flex etc. With years of experiences in pcb industry we also have good channels to get special material so if your product needs special material like rogers, Panasonic, Isola, Ta conic etc pls always email us freely.

PCB General Capability Parameter

- Maximum of 64 layers of PCB processing technology, the minimum line width/spacing 2.5/2.5mil, the highest board thickness aperture ratio of 20:1;

- Gold finger processing technology and precise control of high-density line, to meet the requirements of the optoelectronic communication field circuit board design;

- High-precision mechanical and laser drill process technology to achieve multi-level blind/buried vias structure, to meet the requirements of complex product structure;

- Proven back-drilling technology to reduce the interference from other noise signal to meet the integrity of signal transmission requirements;

- The metal base and super-thick copper manufacturing capacity, to meet the high current and high heat dissipation requirements of the power products:

- The mixing and pressing of FR-4 and high frequency materials, to meet the high-frequency performance of products while a great save the cost;

- The leading buried resistor and buried capacitor technology can greatly reduce the disturbance and improve the performance of PCB products.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|